Edgebanding in Seattle, WA

Welcome to Seattle, Washington, a city nestled between the Puget Sound and the rugged Cascade Mountains, known for its thriving tech scene, diverse culture, and stunning natural beauty. Seattle's innovative spirit extends beyond its renowned technology sector to include a robust manufacturing and design industry, with edgebanding playing a significant role in furniture manufacturing, interior design, and architectural construction. Let's explore how edgebanding enriches Seattle's industrial landscape and fosters creative expression.

Overview:

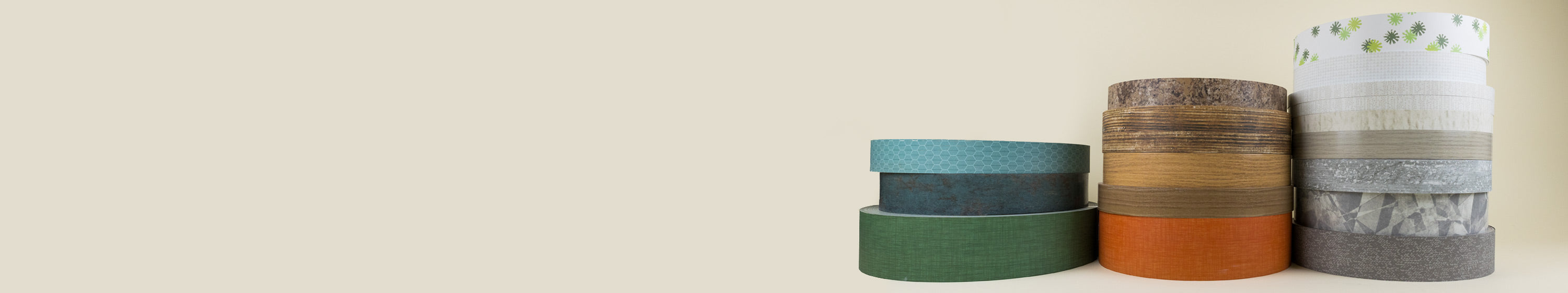

Edgebanding is a crucial process in the production of furniture, cabinetry, and architectural elements. It involves applying a thin strip of material—such as wood veneer, PVC, or acrylic—to the exposed edges of substrates like plywood, particleboard, or MDF (medium-density fiberboard). This technique not only enhances the visual appeal of finished products but also provides protection against moisture, impacts, and general wear and tear.

Industry Presence: Seattle boasts a thriving edgebanding industry, supported by skilled craftsmen, innovative manufacturers, and cutting-edge technology. Local companies specialize in providing edgebanding solutions for residential, commercial, and industrial projects. Whether it's crafting custom pieces for individual clients or executing large-scale production runs for corporate contracts, these firms offer a wide range of services to meet the diverse needs of their clientele.

Technological Advancements: The edgebanding industry in Seattle benefits from advanced technologies such as computer numerical control (CNC) machining, laser edgebanding, and automated finishing systems. These innovations enable precise customization, streamline production processes, and ensure consistent quality control. Seattle remains at the forefront of edgebanding techniques, continually integrating new technologies to enhance efficiency and craftsmanship.

Collaboration and Innovation: Seattle's edgebanding sector thrives on collaboration and innovation, with local manufacturers, designers, and architects working closely together to explore creative solutions and push the boundaries of design. Whether it's experimenting with novel materials, implementing innovative design concepts, or optimizing production methods, the city's edgebanding community is dynamic and forward-thinking, driving the evolution of the industry.

Sustainability Initiatives: Aligned with Seattle's commitment to sustainability, many edgebanding companies in the city prioritize eco-friendly practices and utilize environmentally responsible materials. From sourcing wood from sustainable forests to implementing energy-efficient production processes, these initiatives aim to minimize the industry's environmental impact and promote a more sustainable future for Seattle and beyond.

Training and Education: Seattle's edgebanding industry benefits from a skilled workforce, supported by vocational training programs, apprenticeships, and continuing education opportunities. Local trade schools, technical colleges, and industry associations offer specialized training in woodworking, cabinetmaking, and furniture design, ensuring that the next generation of craftsmen is well-equipped with the knowledge and skills to excel in edgebanding.

Conclusion:

In Seattle, edgebanding represents not only a manufacturing process but also a reflection of the city's tradition of craftsmanship, innovation, and collaboration. With its thriving industry ecosystem, cutting-edge technologies, and commitment to sustainability, Seattle continues to be a leading hub for edgebanding excellence, shaping the future of furniture design and architectural aesthetics. Whether you're a furniture manufacturer, interior designer, or construction professional, Seattle offers a wealth of resources and expertise to bring your edgebanding projects to fruition.